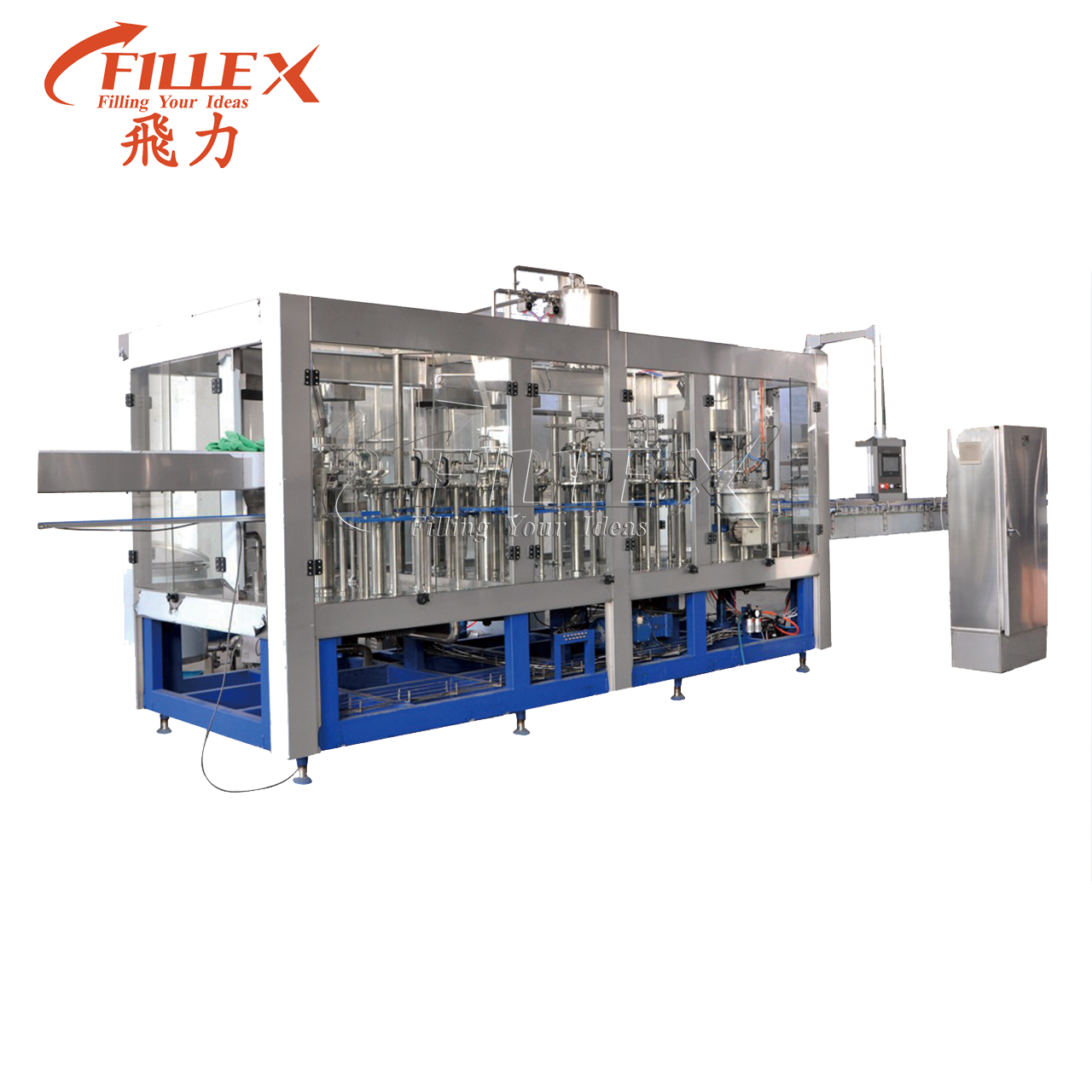

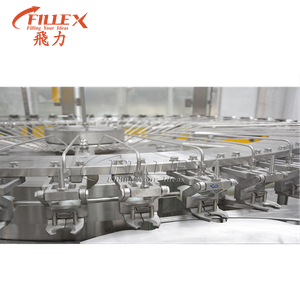

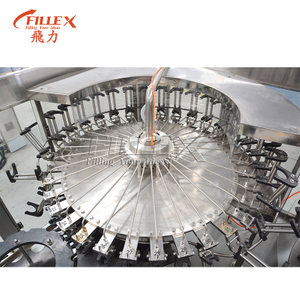

Best juice filling packaging machinery manufacturer 3-in-1 filling monoblock, combined with rinsing, filling and capping. It is innovated and designed in the requirement of non-carbonated energy drinks, functional water, various juice drinks, tea, flavored water, flavored milk on the bases of introducing, digesting and absorbing advanced technology from Germany and Italy.

+86-15062519149 | +86-512-58916707

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

English